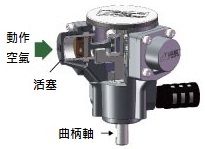

ANEST IWATA's agitators of the Mazeco Series, which employ a radial piston air motor, have the following features when compared to the conventional vane air motors.

The motor can rotate at low speeds without a reducer.

Since the motor does not have a reducer, its structure is simple (consumable parts are fewer).

The rotation speed rarely changes (speed is stable).

Air consumption is reduced significantly (huge energy savings).

The medium-size air motor AM-6B or small-size air motor AM-7B may be selected as appropriate for the paint to be agitated and the facilities to be used.

ANEST IWATA's radial piston air motors all use industrial Vaseline as a lubricant. Since exhaust air contains no extra oil mist, they help improve the coating environment.

Agitating performance far exceeding the conventional notion

While the agitating body of the Mazeco BALL Series agitator is spherical in shape, it offers agitation performance equivalent to that of the conventional propeller- or crown-shaped agitating blades.

It can fully agitate paint not only in the corners of a paint container but also in all the other parts of it such as behind the suction hose.

The agitator can be used to agitate materials other than paint. Both the agitating body and agitation shaft are made of SUS303, the agitator can be used to agitate various kinds of liquid. Note, however, that this agitator is not intended to be used for food or medical applications.

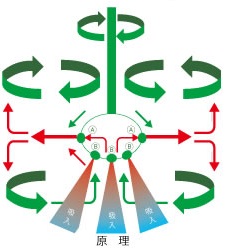

●As the agitating body rotates, centrifugal force is applied to the fluid of horizontal hole (A).

●The fluid discharged from horizontal hole (A) generates negative pressure, causing fluid to be sucked into vertical hole (B).

●The discharged fluid rectifies the eddying flow along the rotating body, thus generating a strong agitating flow.

1、Use of newly designed agitating blades

The AMM-7 Series offers the newly designed three-blade agitator (made of plastics) with the best agitation performance (agitation power and agitating flow) as a standard component.

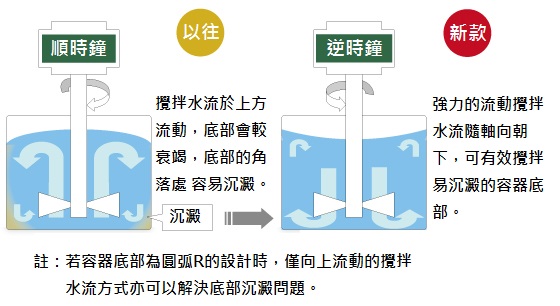

2、Difference in agitating flow direction (AMM-7 Series)

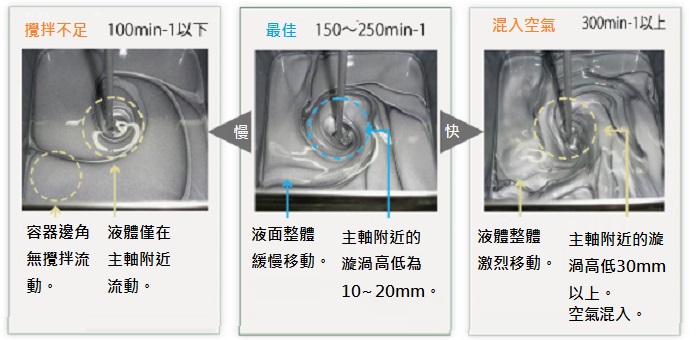

3、Difference in agitation due to rotation speed - from blending to agitation

| Model | Type | Reduction Ratio | Allowable Viscosity Range (Reference) |

Material Used in Agitating Blades |

Material Used in Agitating Shaft |

Mass kg |

| AMM-6B | Hand-Held | 1/1 | 1 Pa・s or less | SUS304 | SUS303 | 2.5 |

| AMM-B6B※ | 1/1 | 0.2 Pa・s or less (60 sec/NK-2 less) |

SUS303 | SUS303 | 3 | |

| AMM-6RB | 1/5 | 4 Pa・s or less | SUS304 | SUS303 | 3 | |

| AMM-611 | Stand Type | 1/1 | 1 Pa・s or less | SUS304 | SUS303 | 4 |

| AMM-631B | Setup Type | 1/1 | 1 Pa・s or less | SUS304 | SUS303 | 2.5 |

| Model | Type | Reduction Ratio | Allowable Viscosity Range (Reference) |

Material Used in Agitating Shaft |

Mass kg |

| AMM-711 | Stand Type (for 16- kg square can) |

1/1 | 60 mPa・s (20 seconds/NK-2) or less |

SUS303 | 2.7 |

| AMM-712 | Stand Type (for 4- kg round can) |

1/1 | SUS303 | 2.7 | |

| AMM-721B | For elevating type DPS pump |

1/1 | SUS303 | 1 | |

| AMM-722B | For HDP pump | 1/1 | SUS303 | 1.1 | |

| AMM-723 | For 20-L pail | 1/1 | SUS303 | 3.5 | |

| AMM-724 | For 16-kg can | 1/1 | SUS303 | 2.9 | |

| AMM-731B | Setup Type | 1/1 | SUS303 | 0.8 |

| Air Motor Model | AM-6B | AM-7B |

| Size | Medium | Small |

| Fluid Used | Air | |

| Rated Air Pressure | 0.5MPa | |

| Operating Air Pressure Range | 0.1~0.5MPa | |

| Operating Environmental Temperature Range | 5~40℃ | |

| Maximum Output | ||

| Operating Air Pressure | 0.5MPa | |

| Output | 63W(0.085hp) | 19W(0.026hp) |

| Torque | 0.48N・m | 0.15N・m |

| Rotation Speed | 1,250min-1(rpm) | 1,200min-1(rpm) |

| Air Consumption | 100ℓ/min | 40ℓ/min |

| Rotation Speed 250min-1(rpm) | ||

| Operating Air Pressure | 0.5MPa | |

| Torque | 0.88N・m | 0.31N・m |

| Air Consumption | 70ℓ/min | 27ℓ/min |

| Air Inlet/Outlet Screw Diameter | Rc1/4” | Rc1/8” |

| Muffler | Accessory | |

| Mass kg | 1.3 | 0.4 |